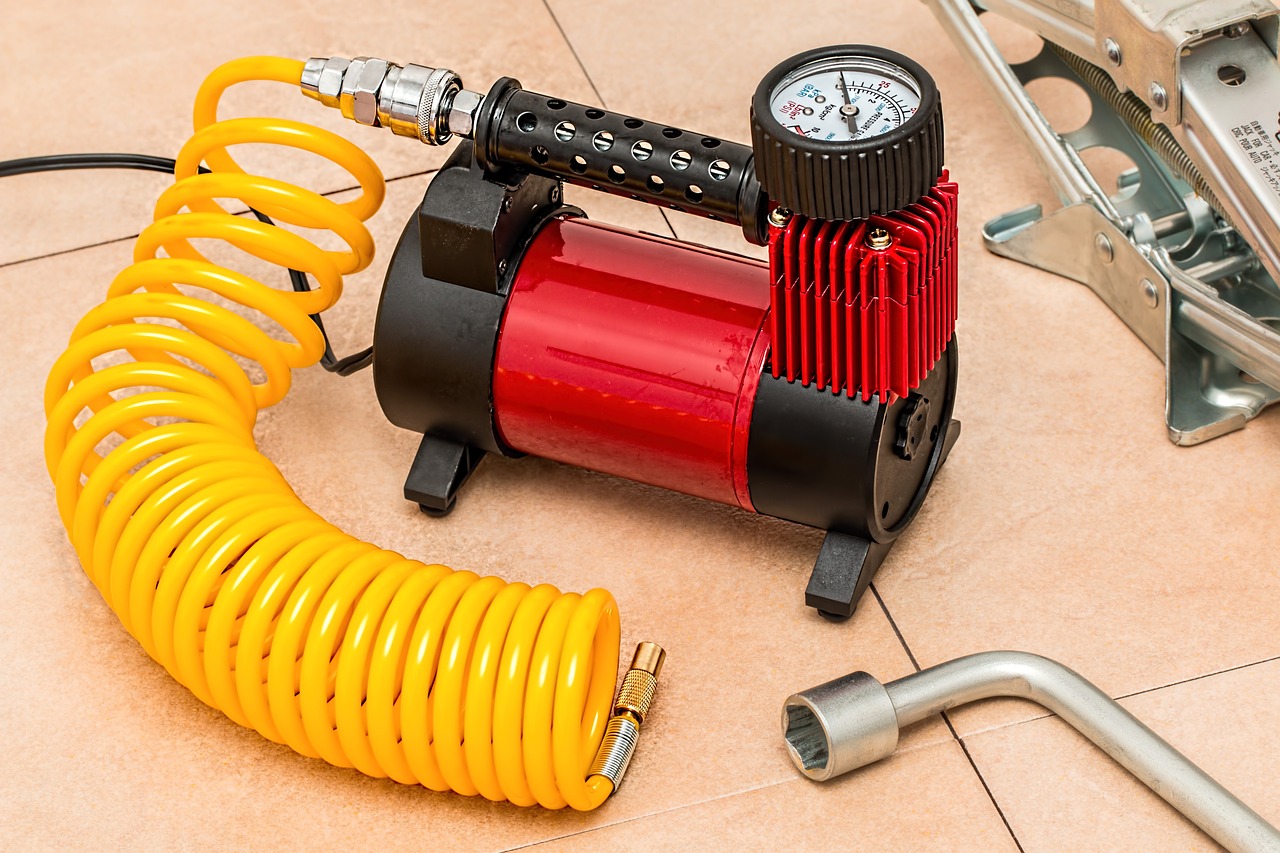

Think of your air compressor as the unsung hero of your workshop or DIY projects. It quietly powers those nail guns, inflates tires with ease, and handles countless tasks with a satisfying blast of air. But like any hardworking machine, neglect will eventually lead to a sputtering performance, costly repairs, and frustrating downtime.

The good news is that air compressor servicing isn’t nearly as complicated as you might think. With a little routine maintenance, you can significantly extend its lifespan, keep repair bills at bay, and ensure your air supply is always ready when you need it. If the idea of tinkering under the hood makes you nervous, relax – most preventative maintenance tasks are well within reach, even for those who aren’t master mechanics.

Air Compressor Maintenance 101

Let’s get to know the key parts of your air compressor that need a little regular TLC to stay in top shape. Think of it like a car – it needs more than just gas to keep going.

- Air Filter: Your compressor’s lungs! A dirty filter forces the motor to work harder, reducing power and potentially overheating.

- Oil: Lubrication is vital. Most compressors have an oil reservoir, and checking/changing the oil prevents major wear and tear on the motor.

- Hoses: Cracks and leaks in your air hoses sap power and waste energy. A quick visual check catches problems before they get big.

- Pressure Tank Drain Valve: Moisture builds up in the tank, and can lead to rust. Regular draining is a must!

How often to give these areas attention depends on how heavily you use your compressor. Think of it like this:

- Weekly: Quick glance at hoses for damage, listen for unusual noises.

- Monthly: Check filter, oil (top up if needed), drain the tank fully.

- Seasonally: Before winter hits, consider seasonal oil changes if specified in your manual.

Don’t worry about memorizing all this – a simple checklist taped to your compressor or saved in your phone makes preventative maintenance easy to stay on top of.

Step-by-Step Preventative Maintenance Tasks

Alright, let’s roll up our sleeves and dive into some practical maintenance! Before you start, the number one safety rule: ALWAYS unplug your air compressor and let the tank depressurize before any work. Eye protection is also smart, especially when working under the unit. You won’t need specialized tools for these tasks:

- Air Filter TLC: Usually a paper filter – some can be tapped clean, others replaced. Your manual tells you which. If it’s super dirty, replacement pays off.

- Oil Check: Most compressors have a sight glass showing the oil level. Follow your manual for top-ups and full oil changes (it’s like a mini oil change for your car).

- Hose Hunt: Run your hand along hoses feeling for cracks or soft spots. Leaks can be subtle. If any are found, replacement is safest before they blow mid-job.

- Drain That Tank: Usually a small valve at the bottom, may need pliers. Wear those safety glasses, as a bit of compressed air (and some rusty gunk) may release.

- Cold Weather Care: If your compressor is outside or in an unheated garage, check your manual for winter oil or instructions on condensation prevention.

It may feel a little awkward the first time, but these tasks get fast and easy with practice. Think of it as building a relationship with your compressor – you’ll even spot potential trouble early, saving yourself headaches (and money) down the road.

When to Consider Air Compressor Servicing

Even the most diligent DIYer sometimes needs to call in reinforcements. While routine maintenance covers a lot, there are situations where professional air compressor servicing is the way to go. Think of it like taking your car in for a tune-up versus just changing your own oil. Specialized technicians have the expertise and tools to diagnose issues beyond typical upkeep. Here’s when to consider pulling up air compressor servicing on your search engine:

- Stubborn Leaks: If there are air leaks you just can’t pinpoint, or that DIY patches don’t fix, a pro can find and repair them properly.

- Eerie Noises: Grinding, squealing, or knocking that wasn’t there before are signs of internal trouble. Don’t ignore it – get it checked out ASAP.

- Power Struggle: If your compressor struggles to reach pressure, or loses it quickly, it’s beyond a clogged filter – there may be valve or motor issues.

Professional servicing also typically includes a full clean and lubrication of internal parts, going deeper than most of us do at home. If your compressor is an expensive model, or crucial to your work, consider annual servicing with a reputable company as a preventative measure.

The Worst-Case Scenario: Emergency Compressor Repair

Let’s face it, sometimes even with the best of care, things go wrong with machinery. Air compressors are tough, but they’re not invincible. If your trusty workhorse suddenly refuses to start, or you hear those ominous clunking sounds, don’t panic, but do put the DIY on hold. There are some situations where you definitely want to find a qualified technician.

Here’s a quick red flag checklist:

- Sparks or a Burning Smell: Electrical problems are nothing to play with. Shut it down immediately and call a pro.

- Dead Motor: If you have basic electrical knowledge and have checked the outlet/fuse, but the motor won’t even hum, it’s not a DIY fix.

- Catastrophic Leaks: Not a slow hiss, but major escaping air means something has failed internally. Time for the experts.

While you wait for help, there ARE some safe things to check:

- Trip Reset: Some compressors have a reset button, check your manual just in case.

- Cord Connections: Make sure it’s securely plugged into a working outlet (test with a lamp to be sure)

Finding fast help minimizes downtime, especially if your compressor is crucial for your business. Don’t just grab the first listing – ask about their emergency service availability, and for a quick phone diagnosis to make sure they’re equipped to handle your specific problem.

Conclusion

Think of those simple maintenance tasks we discussed like an investment in both the flawless use of your air compressor and your own peace of mind. The small amount of time you spend checking it over on a regular basis can save you major headaches and hefty repair bills down the line. Not only will your compressor last longer and perform better, but you’ll avoid those frustrating moments when it fails just as you’re in the middle of an important project.

Learning the ins and outs of your air compressor is surprisingly empowering! Instead of relying solely on a mechanic when problems arise, you have a baseline of knowledge to tackle basic upkeep and even recognize signs of trouble early. That kind of confidence, paired with a reliable and well-maintained air compressor, makes any workshop or DIY project run a whole lot smoother.

Published in: Home advice | Author: Lynn